Quality & Excellence since 1885

WE ARE EQUIPPED WITH STATE-OF-THE-ART CUTTING SYSTEMS THAT PRODUCE TRULY SUPERIOR AND ECONOMICALLY CUT PRODUCTS.

The laser cutting operations at Owen facilitate compressed product development cycles, support just-in-time delivery and produce economical, low-lot-size requirements for one-of-a-kind parts or large production runs. Efficient, automated laser cutting can occur at any time of day with no supervision required.

Our people, processes, and laser cutting equipment provide due diligence, so when the parts hit your production line, they are on time and to your specifications.

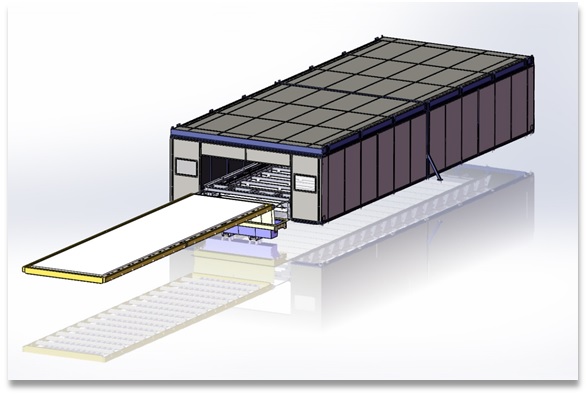

OWEN TO IMPLEMENT A NEW FIBER LASER SHUTTLE SYSTEM CAPABLE OF CUTTING EXTREMELY LARGE PLATES UP TO 128” X 504”.

Owen is installing a new 6 kW Ytterbium Fiber Laser a MetalMaster Xcel from Messer Cutting Systems. The new fiber laser will be capable of cutting massive stainless, aluminum, titanium, brass, copper, and mild steels plates up to 128” x 504”. Paired with one of the world’s largest Red Bud Stretcher-Levelers shuttle bed systems, Owen will be able to process up to eight (8) standard-sized 5’ x 10’ sheets simultaneously.

The new fiber laser will cut Mild Steel up to 1” Thick and Stainless Steel & Aluminum up to 3/4” thick. It produces virtually dross-free cuts on MS up to 3/4″, SS 5/8″, AL up to 1/2″. Additionally, this new system is three times more efficient than CO2 lasers and does not require laser gas making resulting in lower-cost finished products.

About

Owen is dedicated to continuous quality improvement, providing value for our customers, and the pursuit of manufacturing excellence

Technology

Developing industry leading software solutions for our customers, suppliers, and operations

Quality

OWEN ENDEAVORs TO PRODUCE AND DELIVER HIGH-QUALITY PRODUCTS THAT CONSISTENTLY MEET THE EXPECTATIONS AND REQUIREMENTS OF OUR CUSTOMERS

Safety

PROTECTING THE HEALTH AND SAFETY OF EMPLOYEES IS THE TOP PRIORITY AT ALL OWEN FACILITIES

Careers

Isn’t it about time you loved your job?

Industrial & Nuclear Fabrication

As one of the top industrial fabricators in the United States, we produce quality structural steel products for projects up to 20,000 tons worldwide

Metals Processing

First step metals processing with expert capabilities ranging from small, simple cut parts to large, multi-processed components

Powder Coating

Our state-of-the-art, level II powder application system provides advanced coating durability and quality over traditional powder systems

The Slagger

A world-class smoke and slag mitigation system for laser cutting tables.

Steel Castings

WE DESIGN AND PRODUCE INNOVATIVE CASTING SOLUTIONS FOR INDUSTRIES THAT DEMAND OPTIMAL PERFORMANCE AND RELIABILITY

Steel Service Center

A variety of immediately available gauges, grades and sizes of carbon, aluminum and stainless steel