Are you bonding or vulcanizing multiple materials together? Are the small parts becoming too much of a hassle? Are your production costs starting to become a burden? This is where Water Jet Cutting shines.

This challenge comes up more than you would believe. Often times, cutting parts individually and then bonding or vulcanizing them together can become tedious and time consuming. Not to mention the issues with parts not matching up to specification. This frequently leads to lost parts, lost hours and lost profits.

There are times where materials can be bonded or vulcanized and then cut. Unfortunately, the tool needed to cut one material may not work for the other. When this situation occurs, Water Jet Cutting Technology can be a viable solution. There is no HAZ (Heat Affected Zone), thermal distortion or change in material properties which allows multiple materials types to be cut at the same time. Additionally, Water Jet Cutting can support tolerances as close as +/-.005″ with high positional accuracies of +/-.003″.

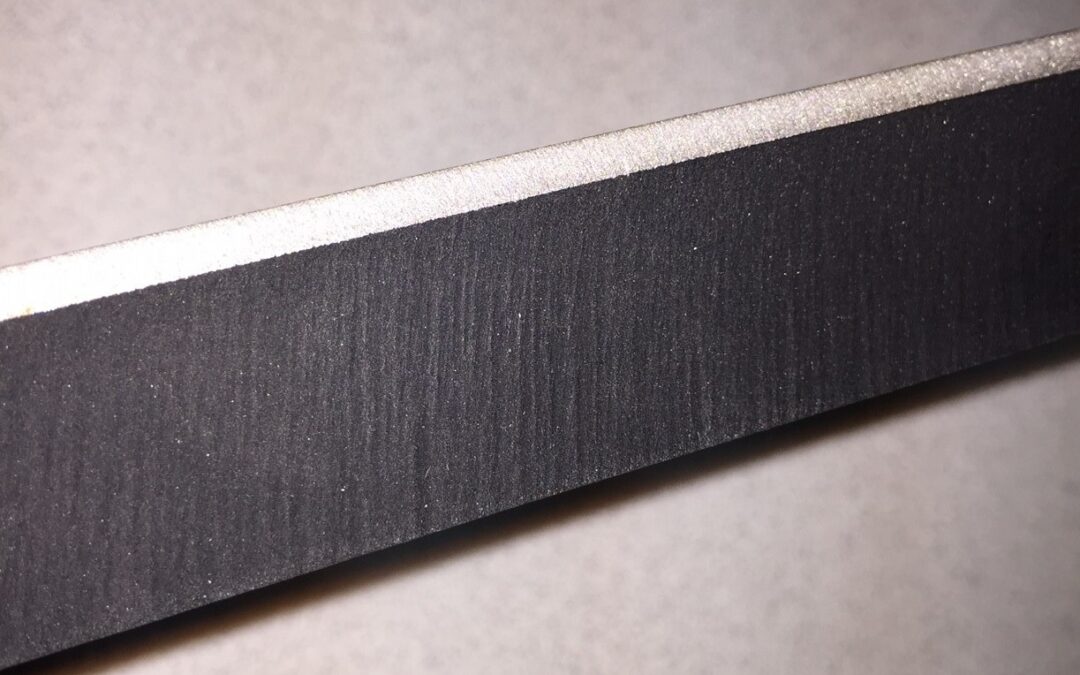

MVS Recently used Water Jet Cutting a Vulcanized Stainless Steel/Duro-Composite Rubber Compound into bumper stops for the Transportation and Agricultural Industry. Rather than cutting each piece separately and then Vulcanizing, MVS received Pre-Vulcanized Full Size Sheets and cut multiple parts, ensuring proper dimensions, fit up, aesthetics and function.

Do you have issues with bonding or vulcanizing materials to create the specified part? Contact Aaron Mousel at amousel@mvsteel.com or call 712-255-9632 or our sales team for information and pricing about Water Jet Cutting.

About

Owen is dedicated to continuous quality improvement, providing value for our customers, and the pursuit of manufacturing excellence

Technology

Developing industry leading software solutions for our customers, suppliers, and operations

Quality

OWEN ENDEAVORs TO PRODUCE AND DELIVER HIGH-QUALITY PRODUCTS THAT CONSISTENTLY MEET THE EXPECTATIONS AND REQUIREMENTS OF OUR CUSTOMERS

Safety

PROTECTING THE HEALTH AND SAFETY OF EMPLOYEES IS THE TOP PRIORITY AT ALL OWEN FACILITIES

Careers

Isn’t it about time you loved your job?

Industrial & Nuclear Fabrication

As one of the top industrial fabricators in the United States, we produce quality structural steel products for projects up to 20,000 tons worldwide

Metals Processing

First step metals processing with expert capabilities ranging from small, simple cut parts to large, multi-processed components

Powder Coating

Our state-of-the-art, level II powder application system provides advanced coating durability and quality over traditional powder systems

The Slagger

A world-class smoke and slag mitigation system for laser cutting tables.

Steel Castings

WE DESIGN AND PRODUCE INNOVATIVE CASTING SOLUTIONS FOR INDUSTRIES THAT DEMAND OPTIMAL PERFORMANCE AND RELIABILITY

Steel Service Center

A variety of immediately available gauges, grades and sizes of carbon, aluminum and stainless steel