Hollow Structural Sections (HSS), Tube Steel, Structural Tubing and Steel Pipe, just to name a few, are all commonly used terms in the Steel Industry. While it may have many names, and a million times as many uses, there is one thing for certain: We would be lost without it. We would not have car frames to take us to work, no metal scaffolding to aid in the construction of the buildings we work in, and certainly no airplanes to take us on vacation! Square, Round and Rectangular Steel Tubing have supported our great society for over 150 years, and with the right touch of human innovation, will continue to do so for centuries to come!

One of the major challenges of Engineering and Design starts with the question, how? How do we make this work? How do we incorporate our design into a physical product? The answer to a lot of these questions is Manufacturing Technology. This immense arena of technical wizardry and know-how help to bring these ideas into reality, and make the success of our future possible. Owen Industries has been at the forefront of the Steel Manufacturing & Technology Industry for over 130 years, and in that time, has done just that and so much more.

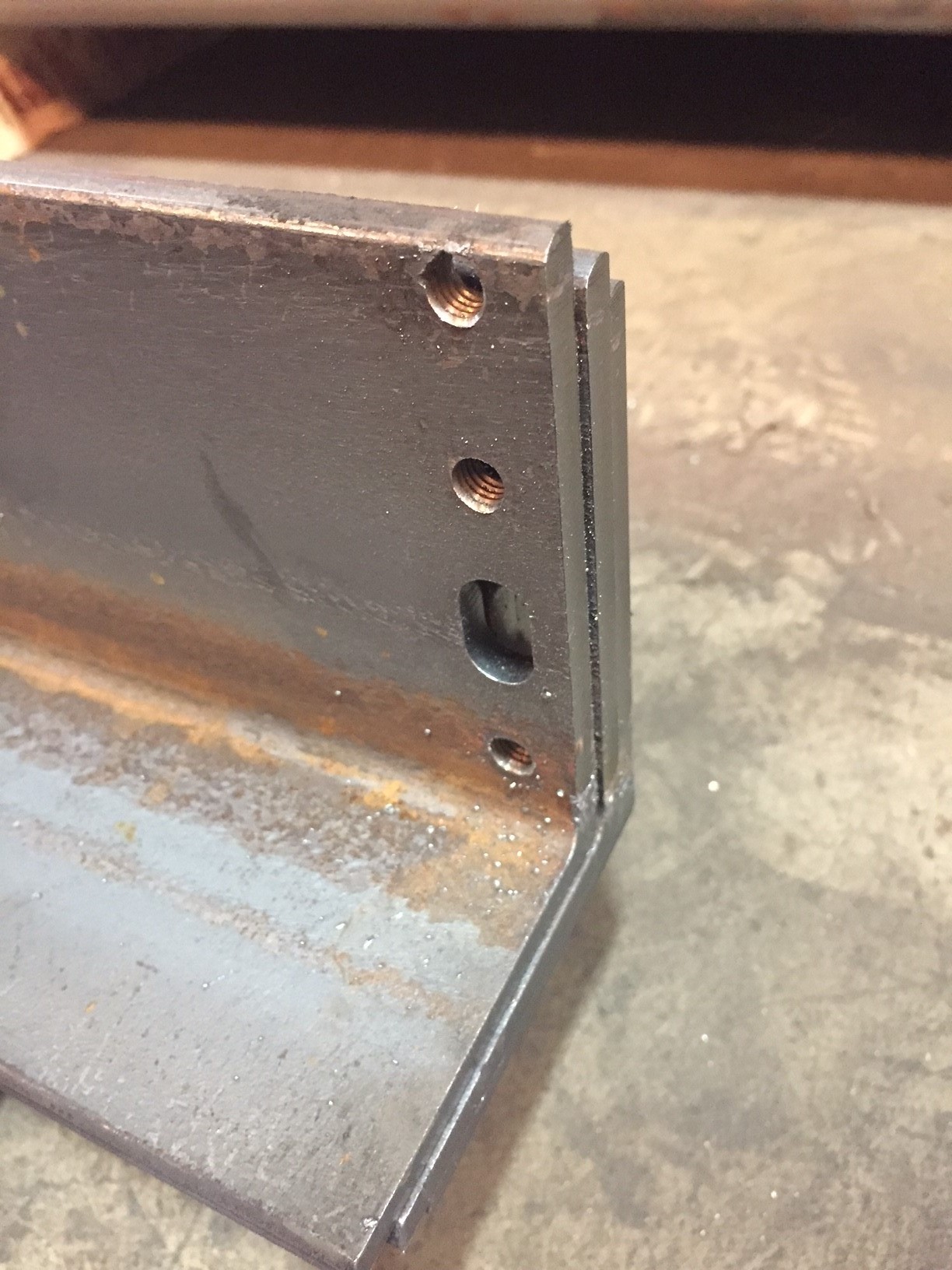

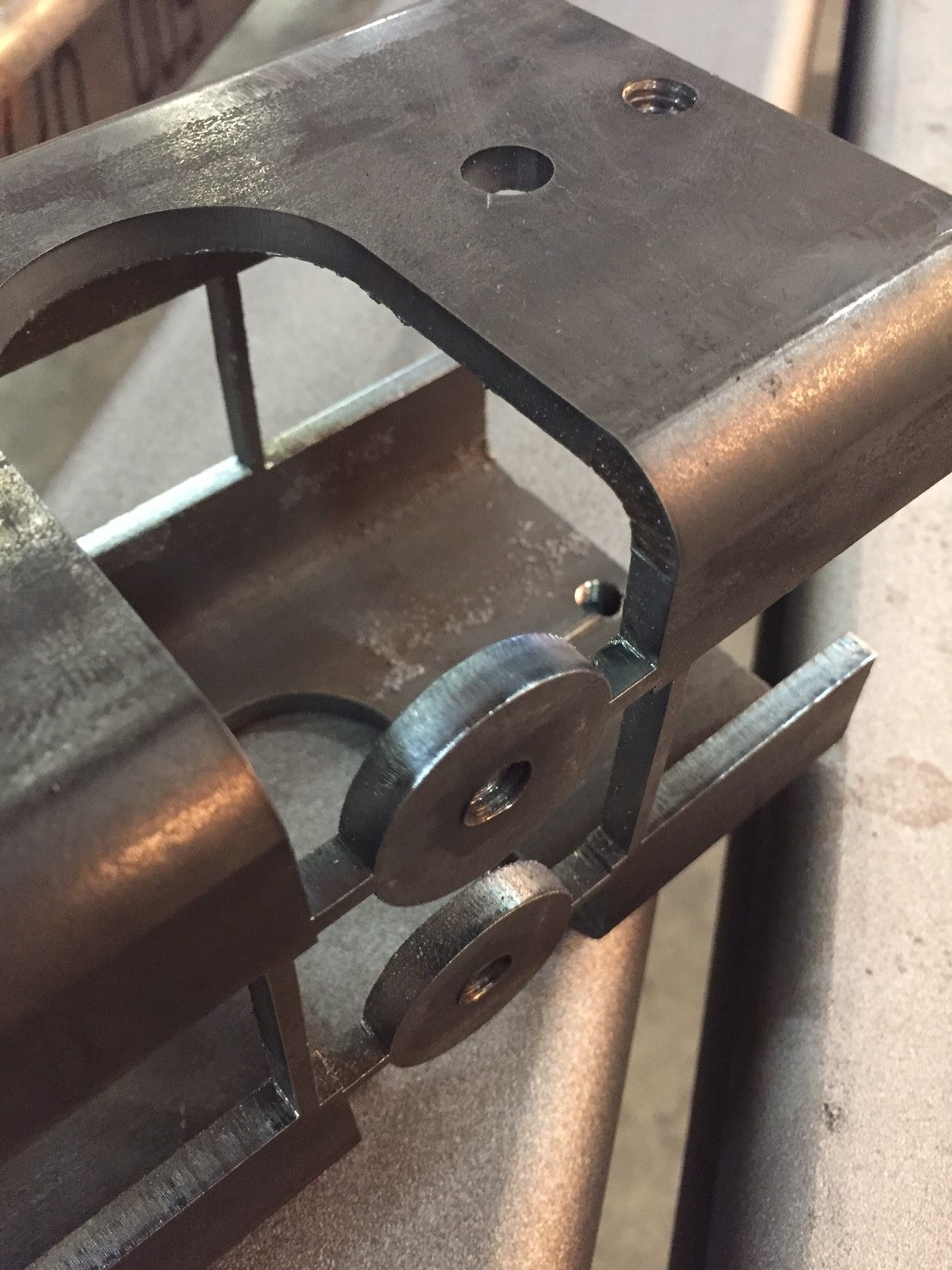

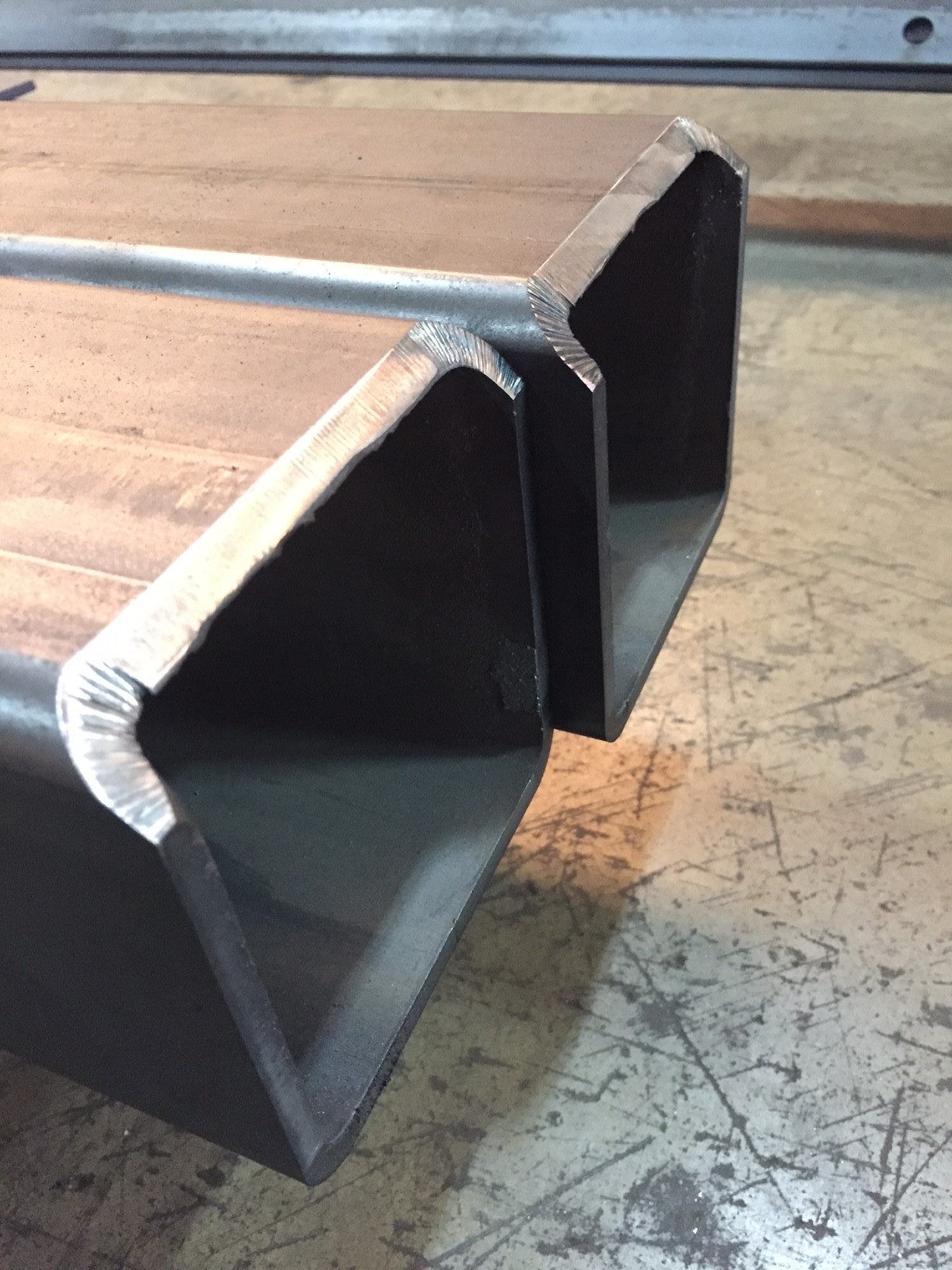

“With Great Power Comes Great Responsibility” and when precisely manufacturing 3-Dimensional Hollow Structural Sections, both power and responsibility are the keys to the machine. Owen Industries owns and operates one of the largest 3D Structural Laser Systems in the Country, capable of processing angle, channel, square, round, rectangular and wide flange shapes up to 48′ – 0″ long and 50# per lineal foot on certain sizes. Limited only to the imagination, this 3D Laser System uses touch sensing technology to cut, bevel and even tap its on holes with accuracies comparable to flat laser systems. If you have a design that needs complex and accurate support, or even straight and simple shapes, please inquire with us at www.owenind.com and get your ideas off the ground today!