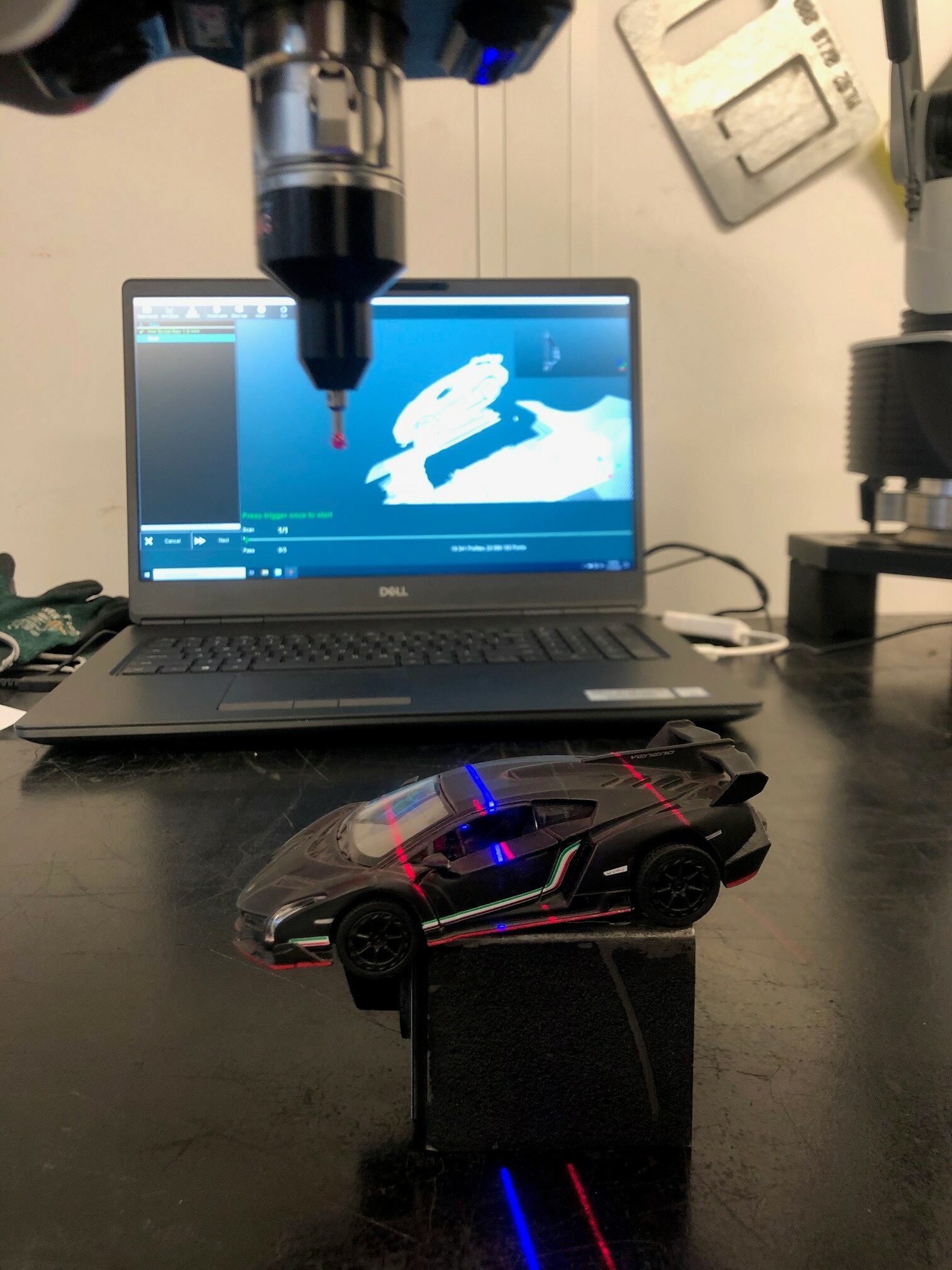

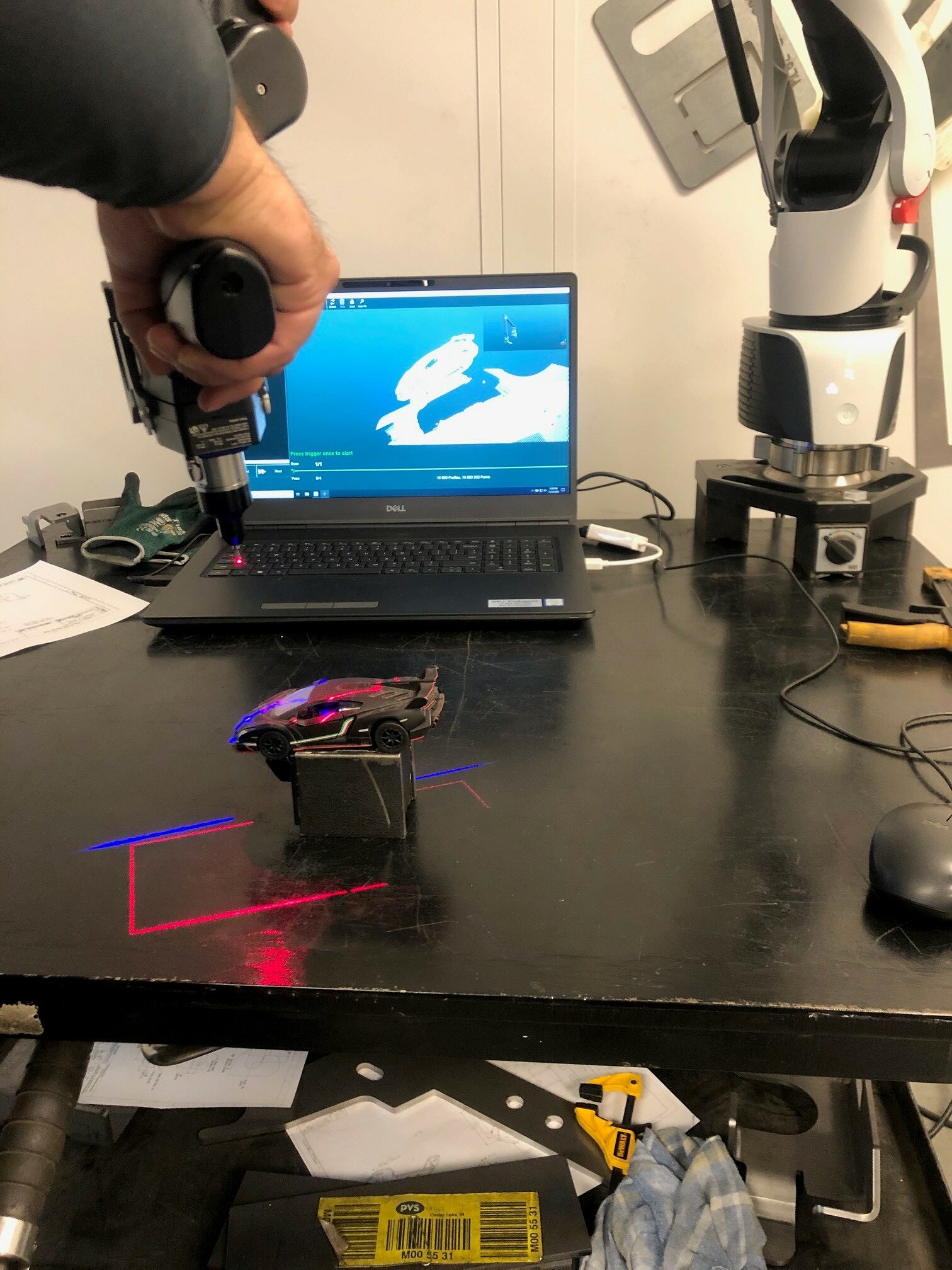

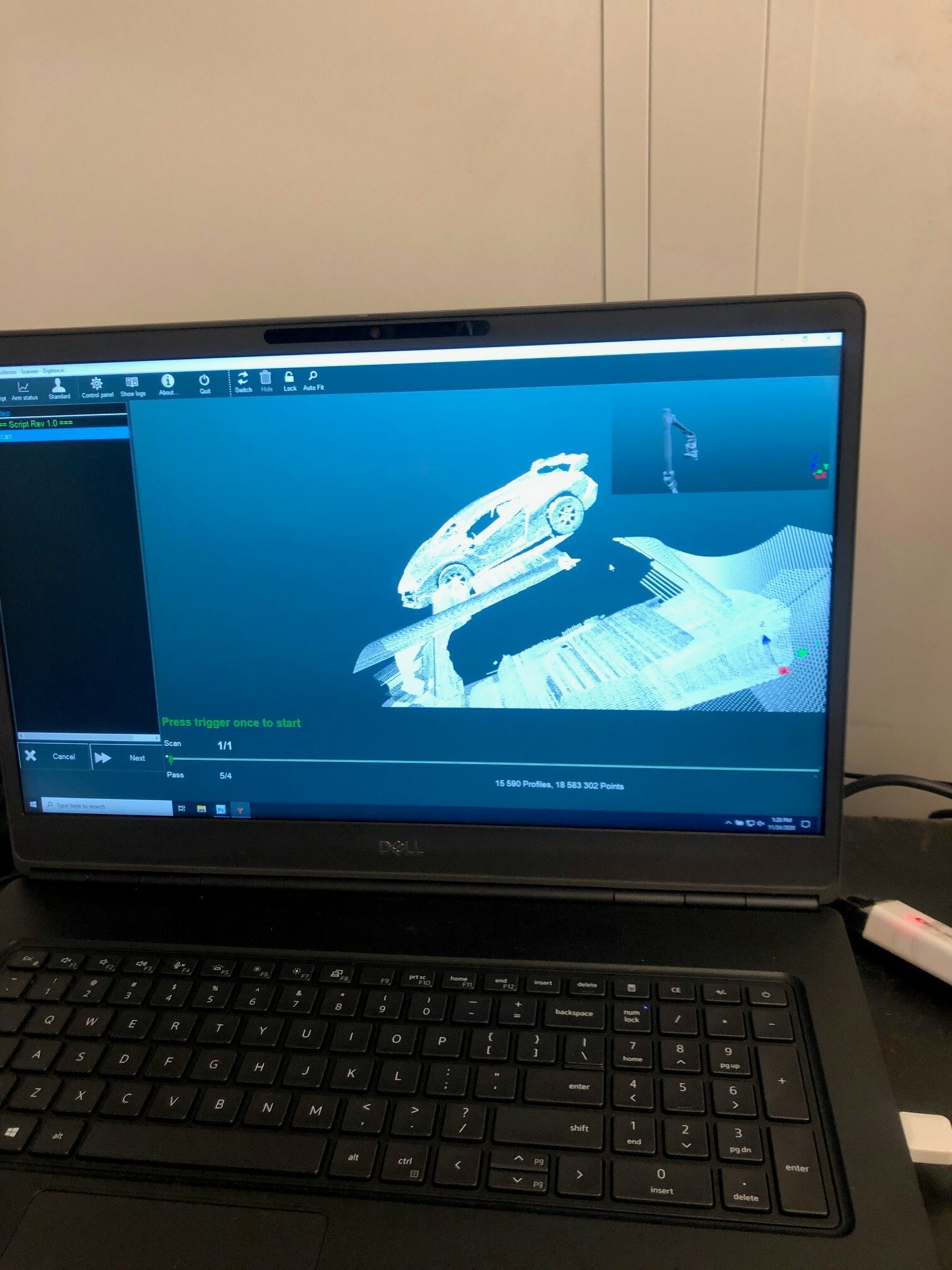

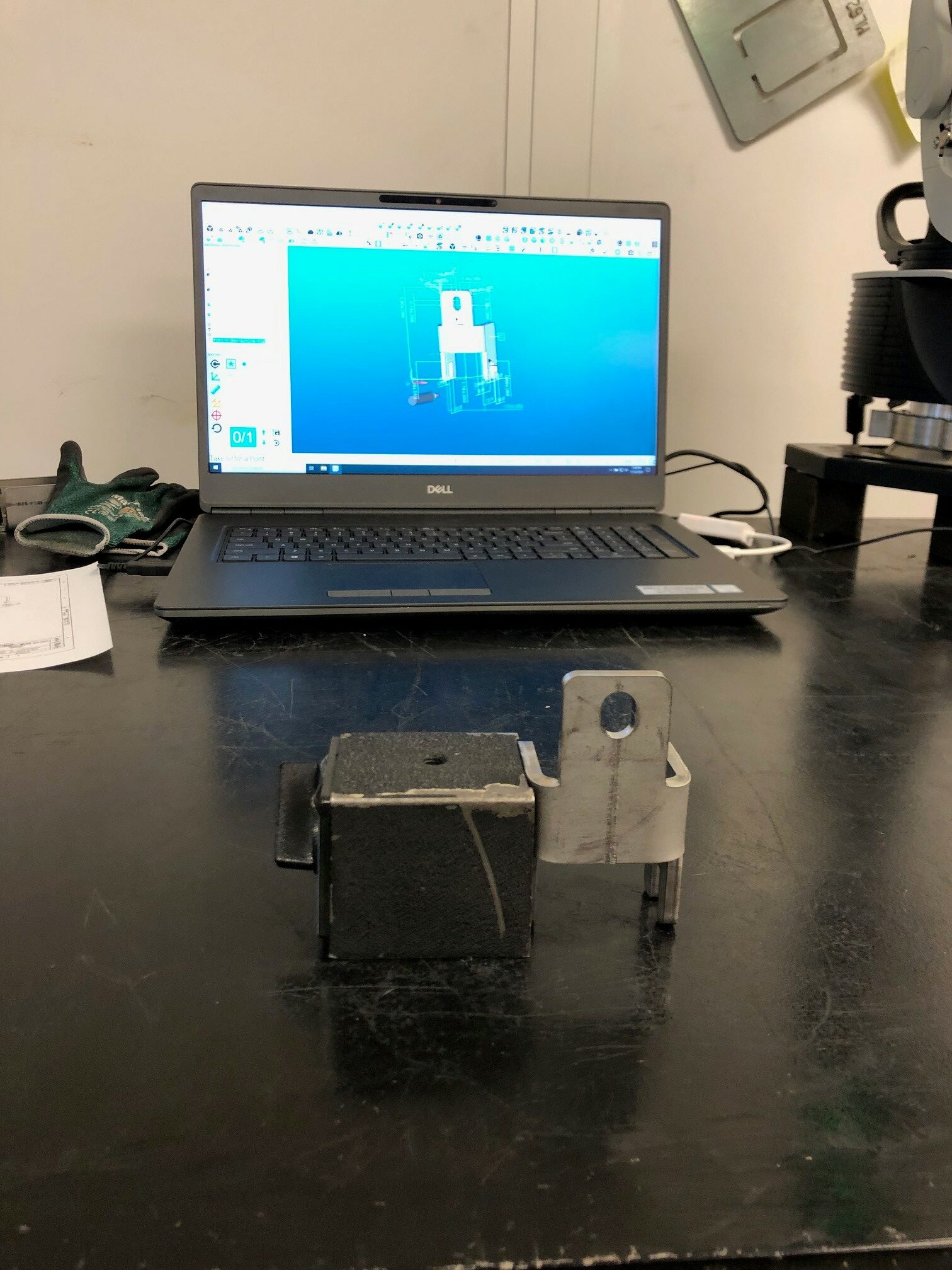

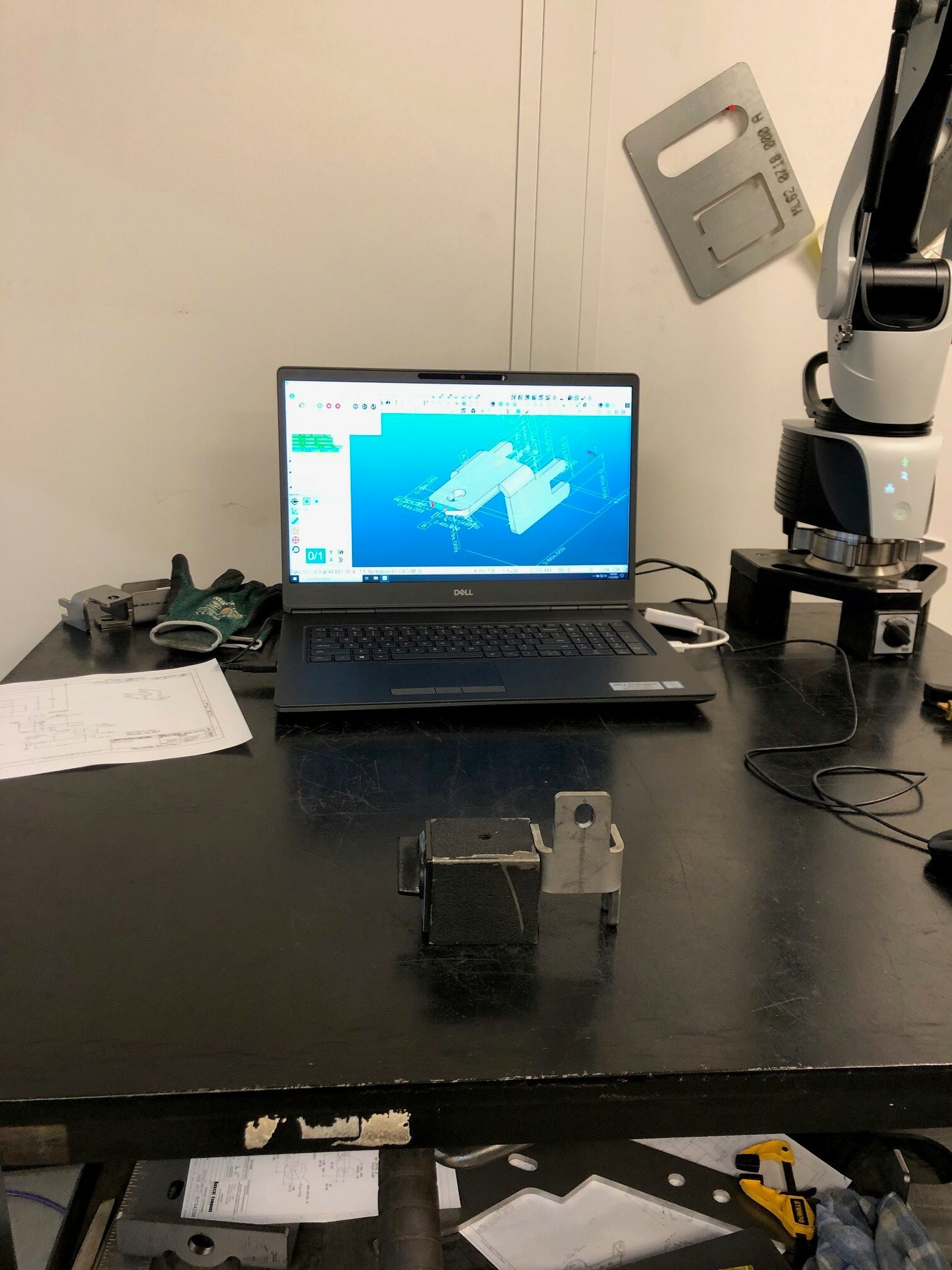

Owen Industries latest addition in quality equipment is the new Hexagon Absolute Arm. This 7-axis probe and scanner combo supports quick scans as well as Part=Cad pulled data point using solid models and comparing nominal to actual data in real time. The PCDMIS software (developed by Hexagon Metrology) fully analyzes a solid model which allows geometric tolerancing to be seamlessly imported and used as a “template” or perfect part to check against what our laser and brakes produce (data could be native to other CAD/CAM software).

This cutting-edge equipment and software allows the PPAP process to be expedited. PVS can now use a solid model of a potential part and completely dimension from beginning to end in a flat or formed view, add in any key characteristics, and simply scan or pull points with the probe. We then mesh the compiled data with the theoretical dimensions that are embedded within the solid model.

This technology is light years beyond what most fab shops are using and is one more reason why PVS Metals is the best solution for your steel fab needs!