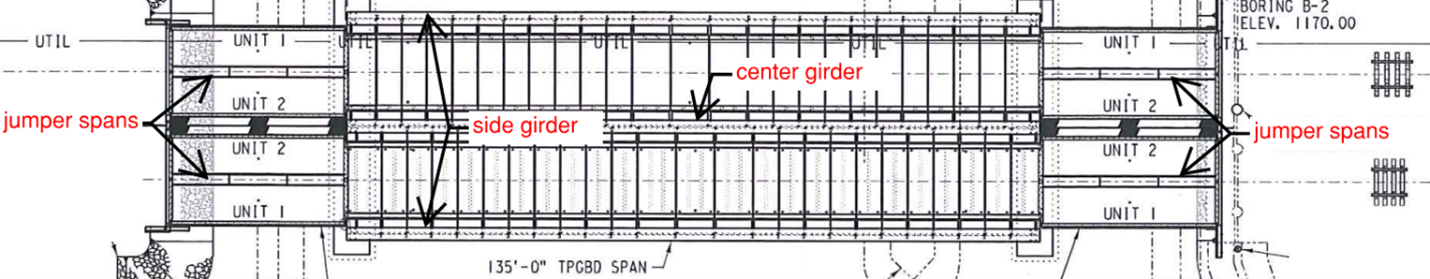

There are three girders providing support for this span, two side and one center (common) girder. Both side girders are identical measuring 2’-6” wide, 11’-11” tall and 135’-0” long weighing 137,400 pounds or 68.7 tons each. Top & bottom flange material is 2” thick and the web plate is 1” thick. The center common girder is 3’-0” wide at the bottom flange and 2’-6” wide at the top, 13’-11” tall and 135’-0” long weighing 211,500 pounds or 105.8 tons. Top flange is 3 ¾” thick, bottom flange is 3” thick and the web plate is 1 1/4” thick. Along with the connecting beams, deck plate and diaphragms, all steel for the TPG span weighs 1,327,340 pounds or 663.7 tons. In addition to the TPG, there are four jumper spans, two at each end of the bridge that are 34-0 long weighing 53,750 pounds or 26.9 tons each.

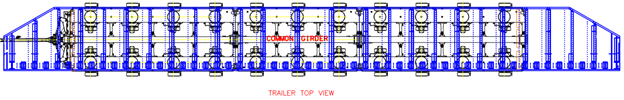

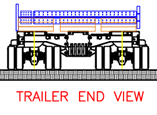

Tractor trailers will be used to haul the 27 loads of steel to the job site. The common girder will have to be laid flat because the center of gravity is too high if shipped vertically. The tractor trailer being used for the common girder (see below) has 11 axel locations with 2 axels per location (see end view). Each axle has 4 tires time 22 equals 88 tires for the trailer alone. Each axle is separate from each other and can be steered independently. A “push tractor” will be attached to the end of the trailer to help the load over hills etc. Front to end the entire load is roughly 192’-0 in length.

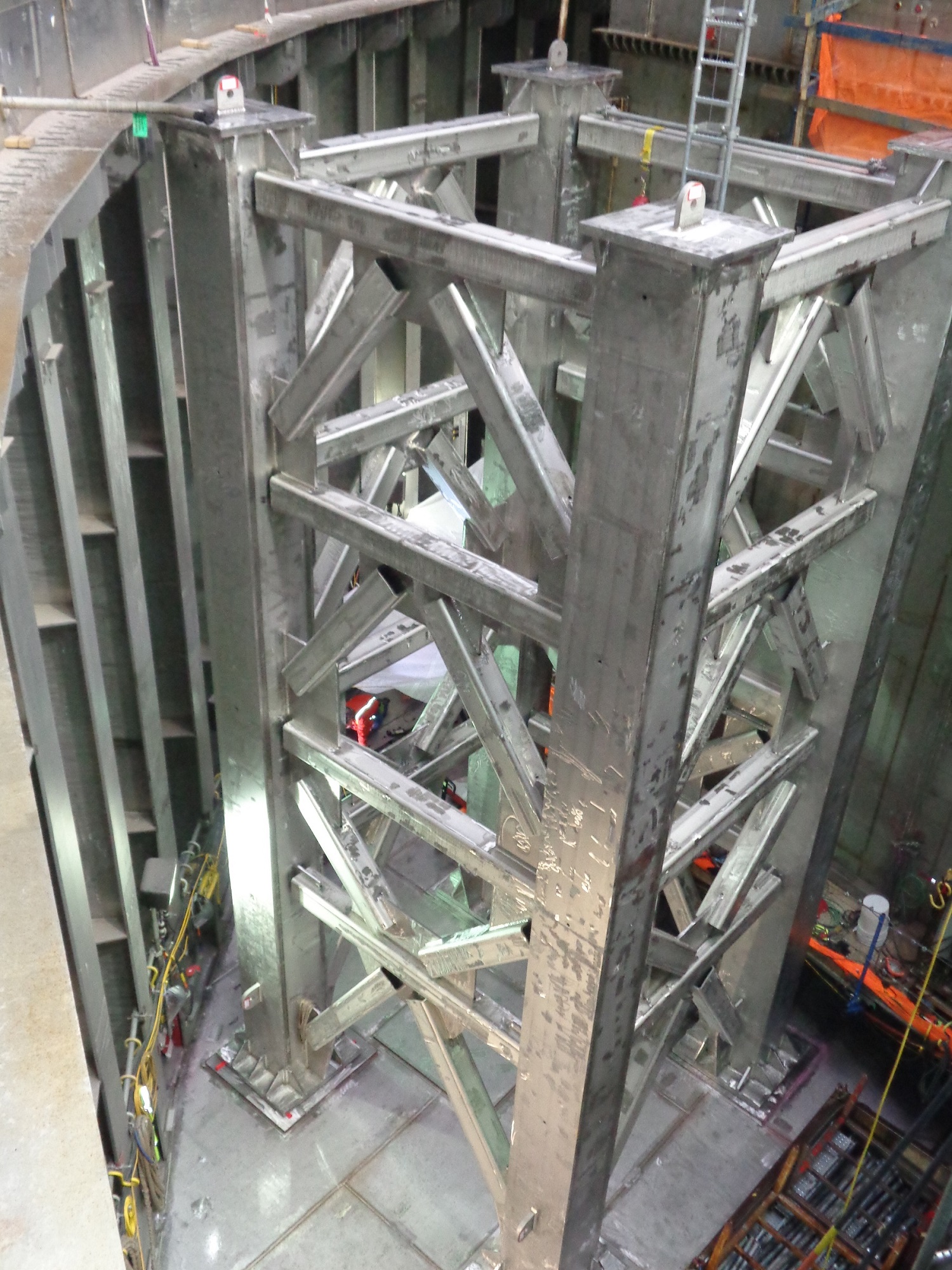

Once the steel is onsite the spans first phase will be built alongside the existing span. after it’s fully erected it will be slid into position with the use of hydraulic pistons and a series of rollers. It will take 4 weeks to assemble phase one steel and ready it for train traffic.