Gears: A Stable of Manufacturing

Lapping Carrier Gears have long been a staple in the building blocks of human civilization. Our early ancestors used wind and water power with a combination of gears to grind grains, seeds, nuts and beans into flour. They used gears to pump water and bellow fire, to track time and to navigate the high seas. There is no doubt that without the invention of the gear, we would not be where we are today.

The advancement of Science and Technology often creates the fuel for its own expansion, with each new frontier requiring intricate and precise parts even more innovative than the last. Lasers require a variety of polished mirrors to redirect, steer or fold beams of photons in simple machines like light curtains, to detecting gravitational waves through space-time with LIGO. Telescopes require highly reflective surfaces to gather and refocus light in order to peer at cosmic targets over 13 billion light years away. While these technologies are without a doubt impressive, they would be nothing without the use of Lapping Carriers.

The Importance of Lapping Carriers

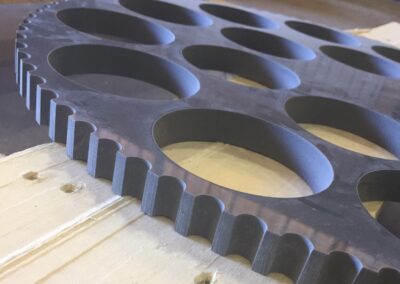

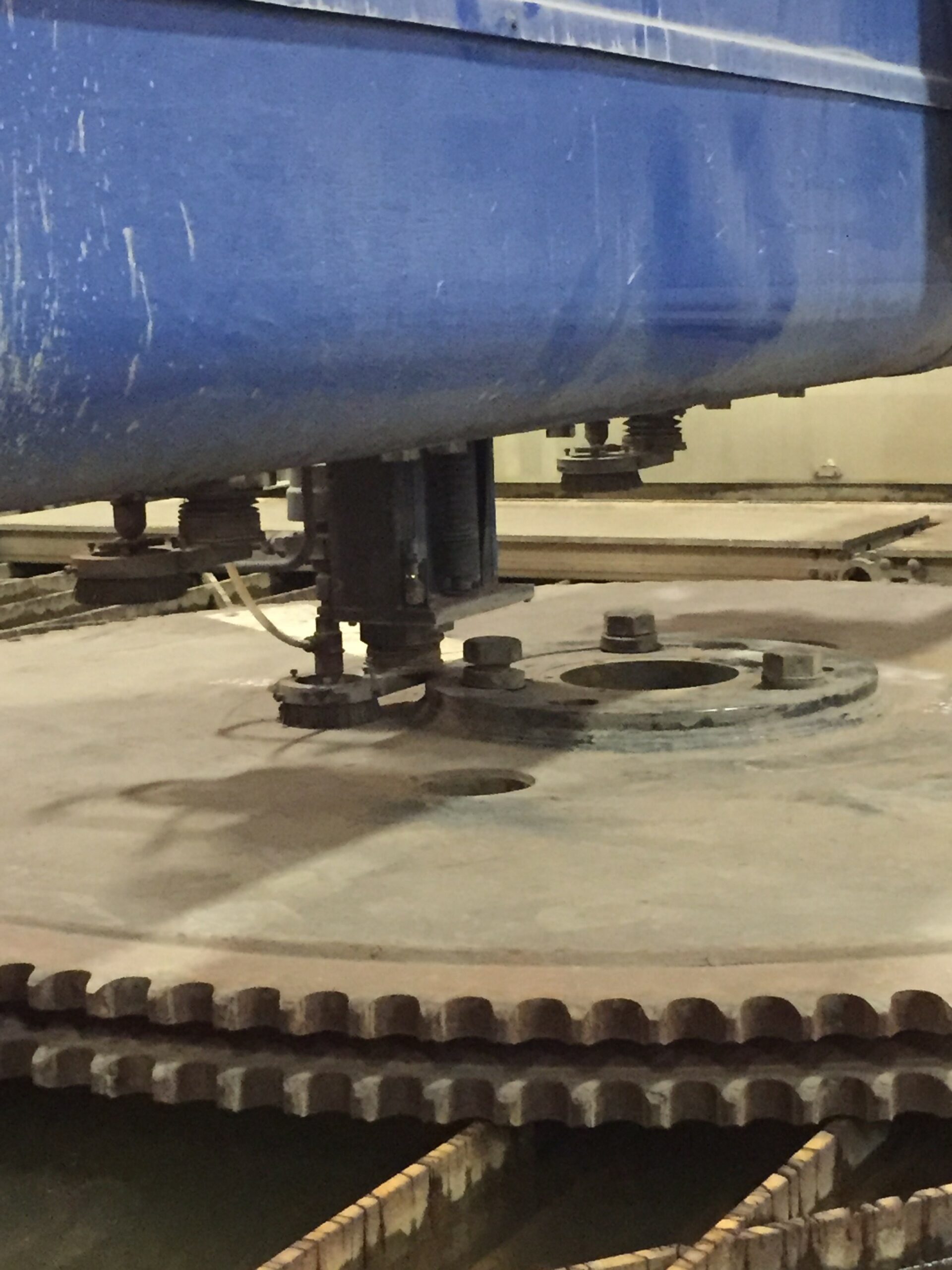

Lapping Carriers are used in a manufacturing process aptly called Lapping, where two surfaces are rubbed together with an abrasive between them when grinding and polishing materials is required. The gear teeth on the Lapping Carrier allow it to be rotated at varying velocities, combined with a library of abrasives, in order to achieve the required finish. Given these conditions, it is paramount that each carrier is produced to a very high and consistent quality. MVS Metals recently had the opportunity of Water Jet cutting some 1/2″ and 3/4” PVC Lapping Carriers for use in the polishing and grinding industry.

For more information on this and other capabilities, please contact us at Owen Industries!