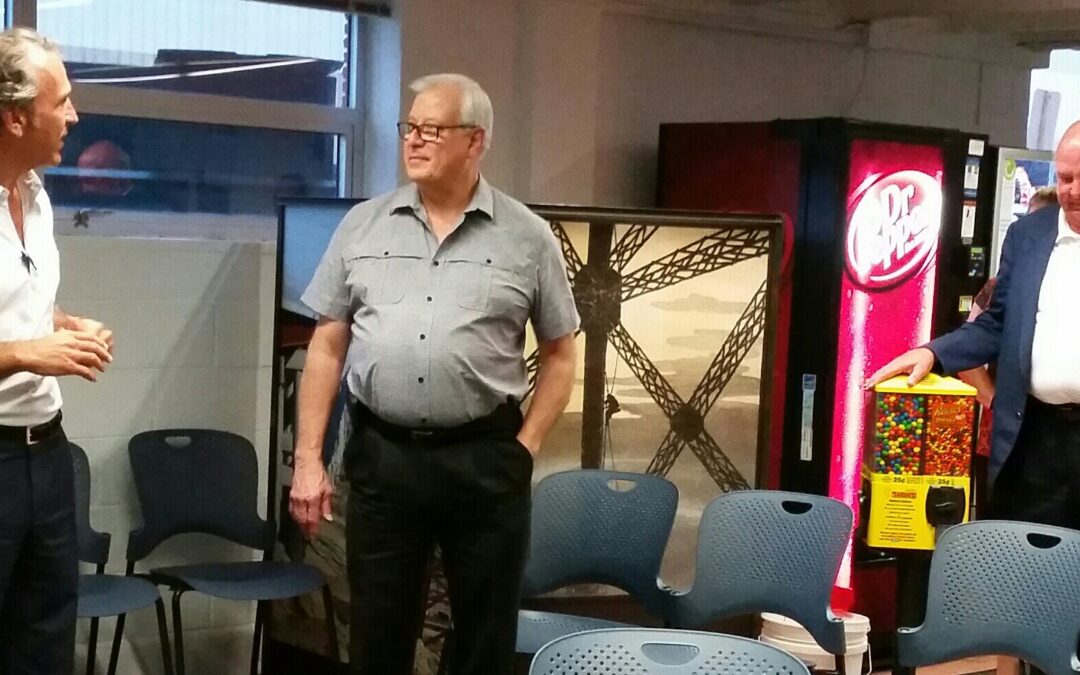

Ed retires after 20 + years!

Ed Korbel started with PVS as CFO in March 1997, he retired August 2017 after 20 + years of service. We interviewed Ed on his tenure with OII.

Owen Industries: What did you value most about you experience working at OII during your many years of tenure?

Ed Korbel: The quality of the people, their desire to excel and achieve the best. There is always something interesting going on at OII.

OII: What do you consider to be the most significant change that helped the company grow?

EK: The addition of SAP and better technology. More information is available, and it’s available faster and better than before.

OII: Do you recall a past project that challenged the team? One of those “They said it can’t be done” projects?

EK: Implementing SAP in 6-7 months, this is typically a task that can take years. Each staff person was paired with a SAP specialist and data was entered into the system. The “Go Live” date as delayed a month due to the office being flooded.

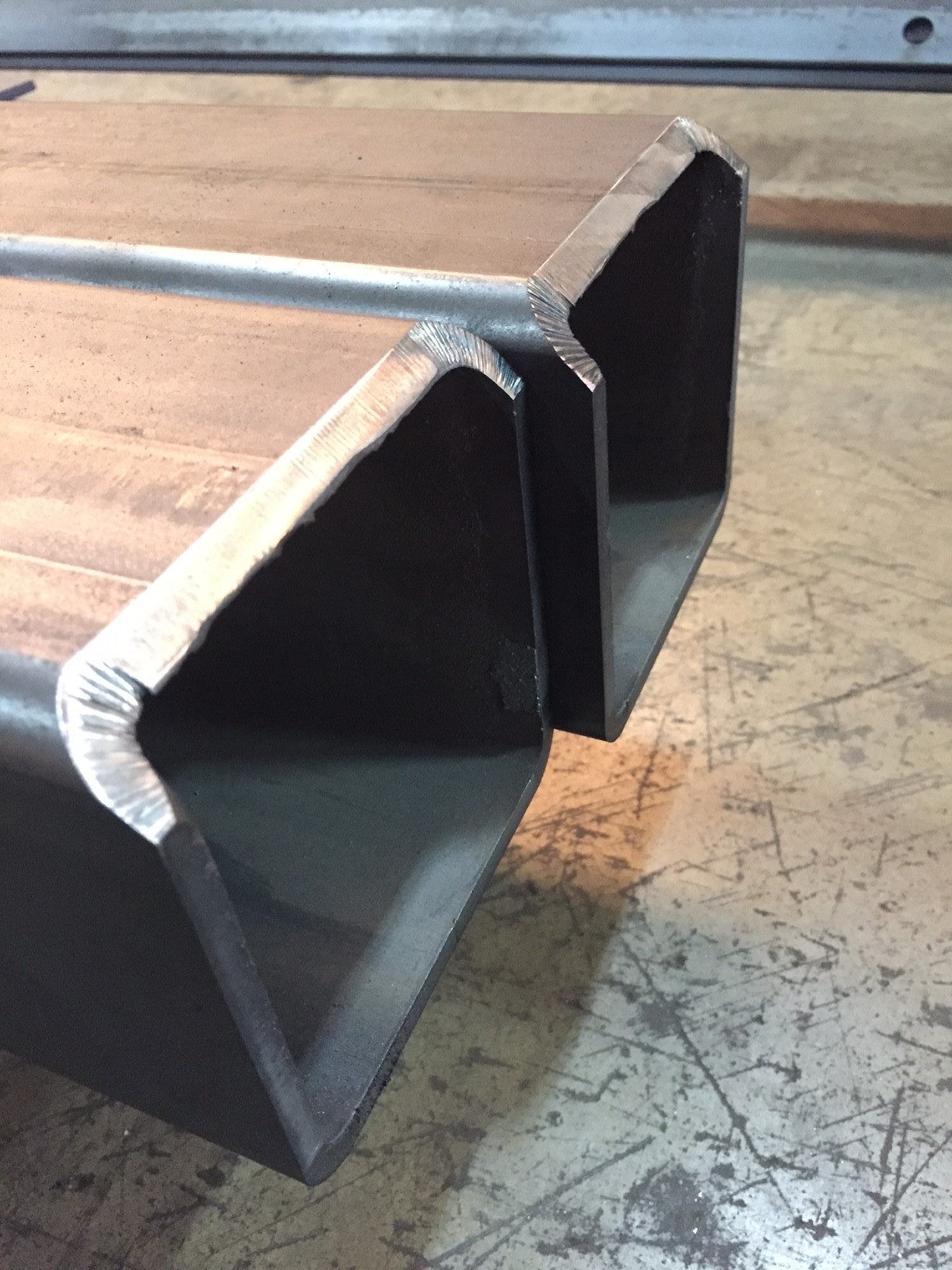

OII: What do you think the future has in store for Owen Industries?

EK: The sky is the limit, with the new Metals building, extra space in Structural Fab, I only see upward movement, OII is positioned to take off.

OII: What’s different from the way things were done your first day on the job from the way they are done now?

EK: Today there is more access to electronic resources; the internet, e-mail, fax, just constant contact through technology. I can fix an issue from home now outside of working hours.

Post retirement Ed will spend his time spoiling his grandchildren, golfing and working on projects at home.